Pressure Release Dampers, Return Air Risers, Pass Boxes & Coving Systems

Essential components for maintaining sterile airflow, controlled material transfer, and hygienic surfaces in modern operating theaters.

Key Features & Benefits

Pressure Release Dampers (PRD)

Automatically relieve excess air pressure while maintaining positive pressure inside OTs.

Prevents door blow-out, maintains stable airflow, and protects sterile zones from contamination.

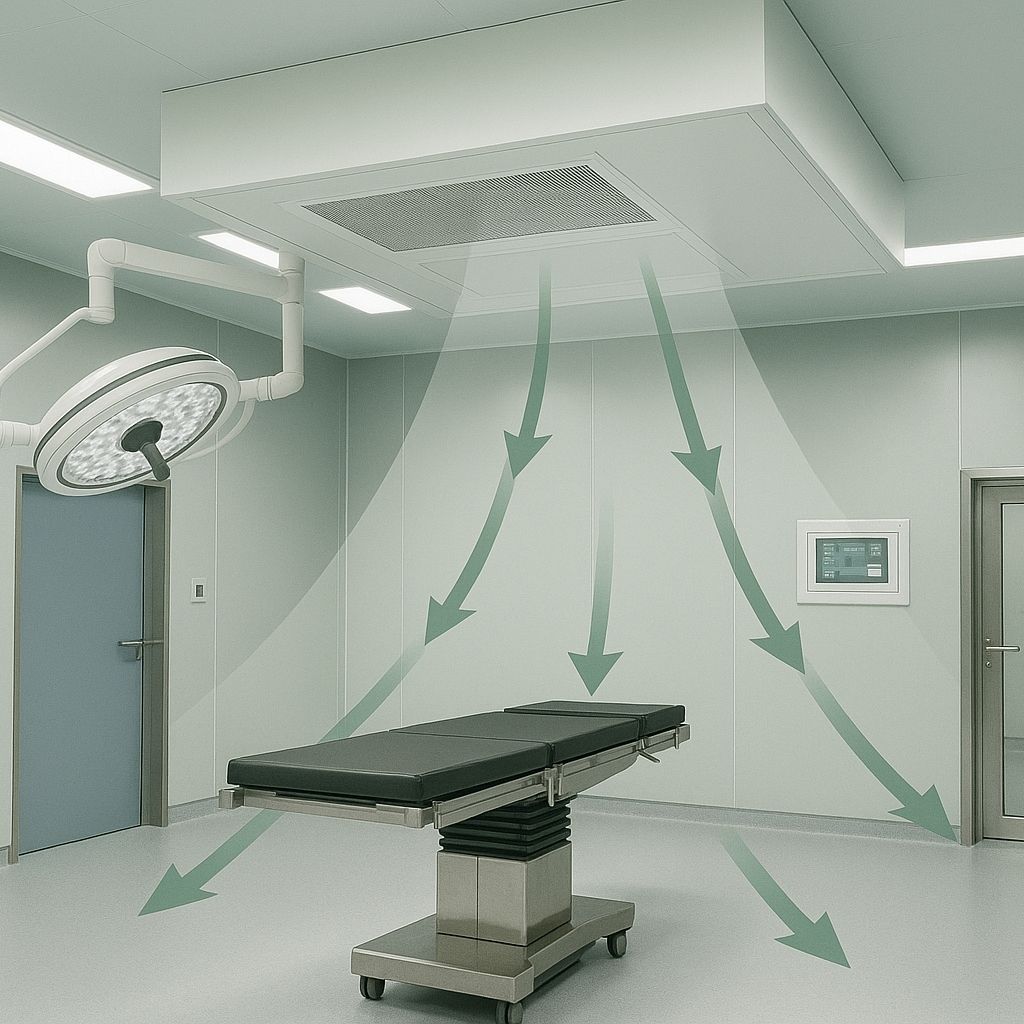

Return Air Risers

Collect spent air from the OT and direct it back to the AHU for filtration or exhaust.

Creates a piston effect that flushes contaminants downward, ensuring efficient air changes and maintaining sterile airflow.

Pass Boxes (Pass-Through Hatches)

Interlocked cabinets for transferring materials between areas of different cleanliness without personnel movement.

Reduces contamination risk, minimizes traffic, and optionally sterilizes items using integrated UV-C lighting.

Coving Systems

Rounded junctions between walls, floors, and ceilings using PVC, aluminum, or stainless steel profiles.

Eliminates crevices, reduces airflow turbulence, facilitates smooth cleaning, and prevents microbial accumulation.

OT Airflow & Hygienic Transfer Systems

Integrated airflow, material transfer, and coving solutions to maintain sterility, reduce contamination, and improve cleaning efficiency in OTs.

Ensure Optimal OT Sterility & Airflow

From pressure control to hygienic material transfer and smooth wall-floor transitions, these systems safeguard sterile environments efficiently.

Our Blog

Latest news updates