Laminar Airflow Systems: Manufacturing LAF Units for Class 100 Environments

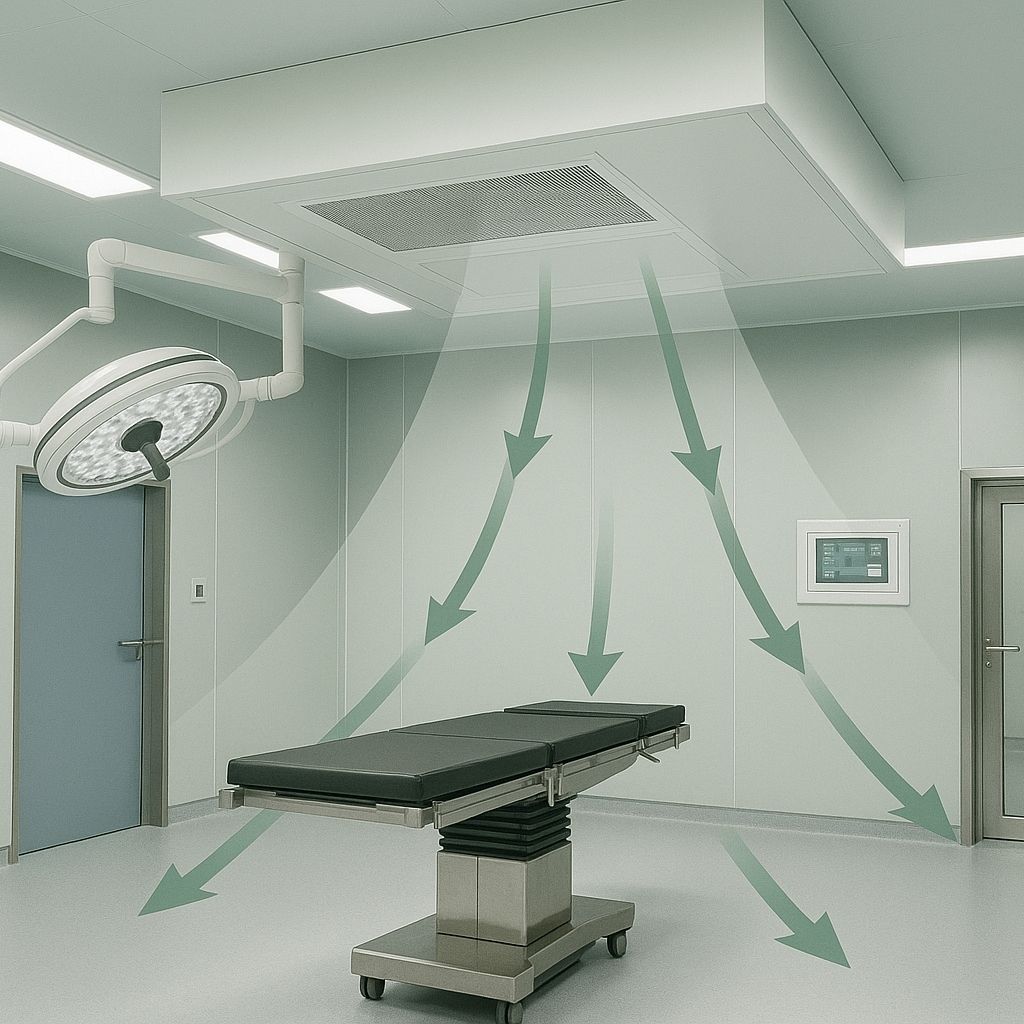

Laminar Airflow (LAF) Systems are precision-engineered units designed to create ultra-clean, particle-free air environments. They deliver highly filtered air in a consistent unidirectional (laminar) stream, sweeping away airborne contaminants. LAF systems are essential in pharmaceuticals, biotechnology, microelectronics, operating theatres, and advanced sterile manufacturing zones requiring ISO Class 5 / Class 100 cleanliness levels.

Engineering Specifications & Performance Benefits

Available Sizes (4×6, 4×8, 6×8, 8×8)

Significance: Size flexibility ensures compatibility with both small workspaces and full OT/sterile zones.

Value: Enables customization based on process requirements and spatial constraints.

Mini-Pleat HEPA Filters

Significance: Core component for achieving ISO Class 5 filtration levels.

Value: 99.99% filtration efficiency at 0.3 microns, extended lifespan & low energy consumption.

SS-304 Plenum Chamber

Significance: Ensures uniform pressure and air distribution before HEPA output.

Value: Corrosion-resistant, hygienic, and zero particle shedding for sterile environments.

Silent Airflow Technology

Significance: Designed to minimize vibration and noise during operation.

Value: Improved operator comfort and reduced disturbance in hospitals & labs.

99.99% Filtration Efficiency

Significance: Critical for maintaining airborne sterility in operating and sterile manufacturing zones.

Value: Removes spores, bacteria, and micro-particles ensuring stable Class 100 compliance.

Uniform Downstream Airflow Distribution

Significance: Ensures consistent airflow velocity with zero turbulence.

Value: Creates an ideal piston-effect airflow pattern for contamination control.

Precision-Engineered Laminar Airflow Unit

Engineered for ISO Class 5 / Class 100 air performance — trusted in pharma, OT environments, and precision labs.

Looking for a Customized Laminar Airflow Solution?

We design and manufacture LAF systems tailored to your process, compliance, and cleanroom needs.

Our Blog

Latest news updates