HVAC & Airflow Engineering: Built to NABH Standards

Our HVAC systems are engineered specifically for healthcare environments, ensuring controlled airflow, sterility, safety, and compliance with NABH guidelines. Every parameter supports surgical precision and long-term operational reliability.

20 Air Changes Per Hour (ACH)

Purpose: Ensures continuous air replacement.

Benefit: Reduces airborne infection & contaminants.

Air Velocity: 25–35 FPM

Purpose: Enables laminar airflow precision.

Benefit: Maintains sterile surgical zones.

15–20% Fresh Air Intake

Purpose: Ensures healthy indoor air quality.

Benefit: Supports pressure balance & ventilation.

Positive Pressure: 2.5 Pa

Purpose: Prevents contaminated air entry.

Benefit: Maintains sterile conditions during operations.

Multi-Stage Filtration

Included: Pre-filter (10μ) + Fine filter (5μ).

Benefit: Extends HEPA life & improves safety.

HEPA 99.97% @ 0.3 Micron

Purpose: Final-stage critical filtration.

Benefit: Removes microbes & micro-contaminants.

VFD-Controlled System

Purpose: Smart airflow + energy optimization.

Benefit: Accurate control with reduced power cost.

Low-Noise, Anti-Vibration Design

Purpose: Reduces operational disturbances.

Benefit: Enhances staff focus & patient safety.

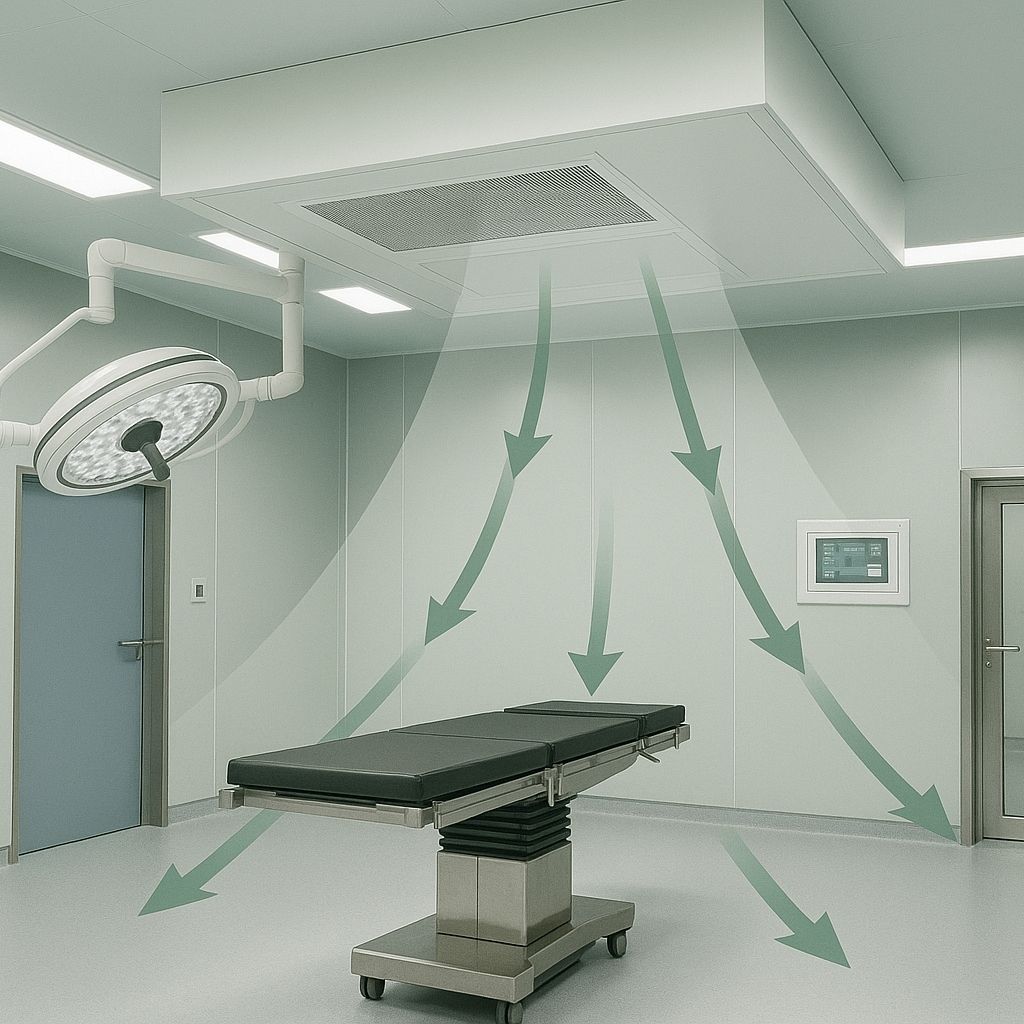

Precision-Engineered Airflow System

Designed for NABH-compliant airflow performance — ensuring sterility, control, and operational efficiency.

Ready to Build Your Modular OT?

Your project deserves precision engineering and expert guidance.

Our Blog

Latest news updates